Project Stratford Station Entrances

Multiple Station Entrances

Major works on Stratford Station have spanned multiple projects and disciplines. From the initial groundworks and civils to build the new platform 3a to four entrances to allow connections and increased capacity as well as station wide handrails, bracketry, architectural finishes.

2015

Year

£750,000

Overall Value

JNG Construction / Tubelines Ltd.

Client

Jay Olivant

Contact

The Challange

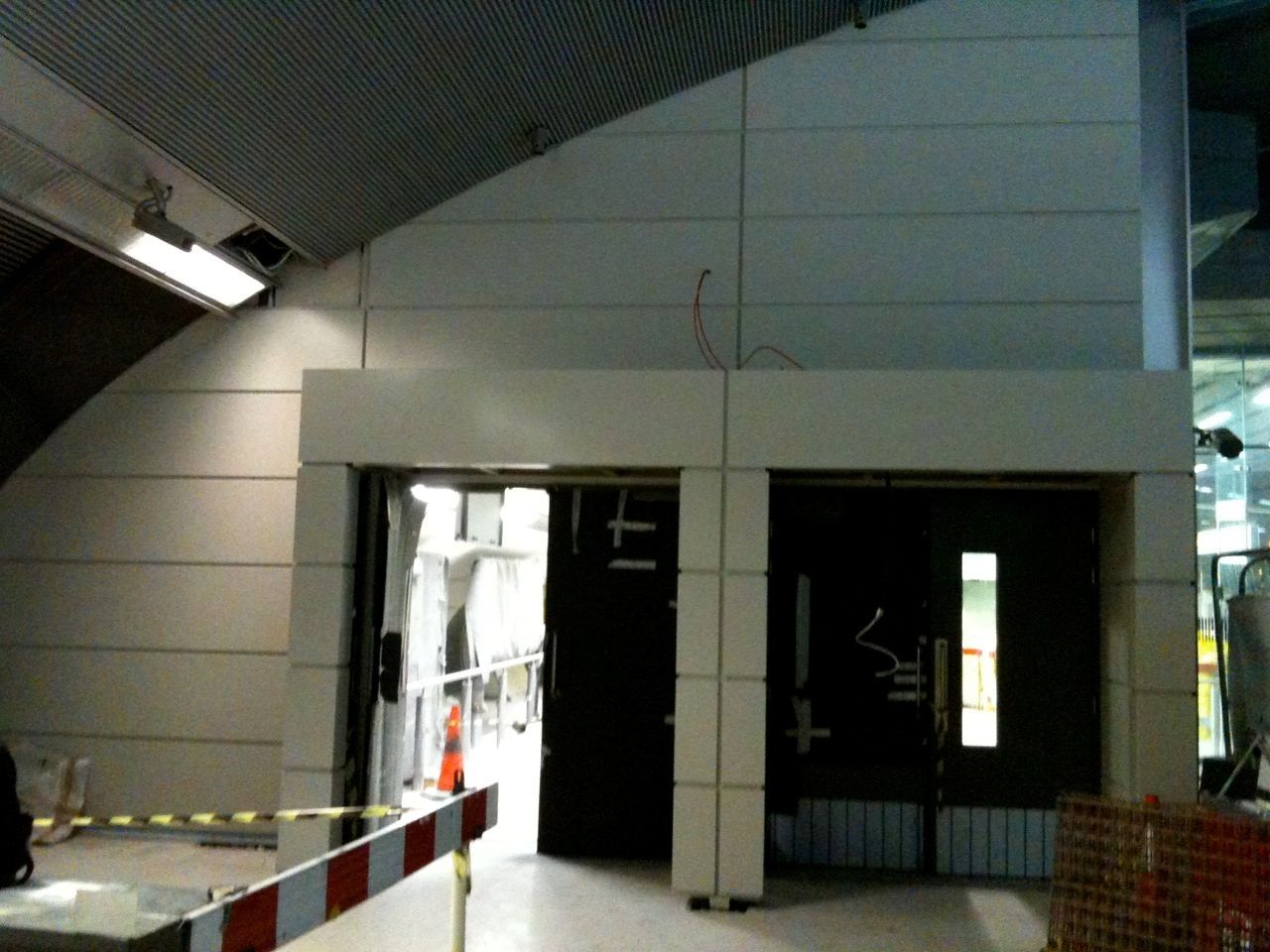

Gridline 17a – A new mezzanine entrance was constructed as part of the station upgrade but an area between the old station and the new extension had left a 3m area that was not within the scope of works of either of the main contractors. Spoor-tech where engaged to install piled foundations and ground beams to the basement area to support structural steelwork and a 40m2 structural slab infill between these areas. Station level works included a rainscreen cladding portal entrance and automatic fire doors. VALUE - £300k

Mezzanine and platform 3a Entrance – in order to increase capacity, a new entrance was required directly adjacent to the main mezzanine level entrance. This was required to mirror the entrance and included glazing, structural steelwork, secondary support members, bostwick gates and enclosures and new matwells, signage and finishes. VALUE - £220k

Street Level Southern concourse entrance – A temporary entrance was formed by TLL to increase pedestrian flow ahead of the London Olympics. These works were functional and Spoor-Tech were engaged in 2015 to modify the existing installation to more closely mirror the existing entrances previously worked on by us and fabricate and install architectural steelwork to create a permanent entrance for adoption. VALUE - £100k

Structural engineering support was undertaken by our highly experienced sub-contractors, who brought an intimate knowledge of the required standards and project requirements.

The client supplied a brief outline scheme that was further developed by our in-house CAD support.

Over multiple projects on this flagship station, Spoortech have been engaged to design, supply and install entrances to all areas, the packages were let with minimal information but on the strength of previous projects we understood that the various entrances required designs that closely matched the existing adjacent entrances and finishes.

All structural and architectural steelwork was manufactured under CE standards and ensured the quality of materials and processes were all fully traceable and handover documentation was available soon after completion.