Project Kings Cross Camden Sewer

Supply and install new sewer culvert sections

In order to facilitate the lowering of the existing track level on the Kings Cross Remodeling Project would require the complete replacement and decommissioning of a brick sewer directly beneath the existing track. The majority of the works could be undertaken off-line but the section below the tracks would be undertaken during a full closure over Christmas 2020.

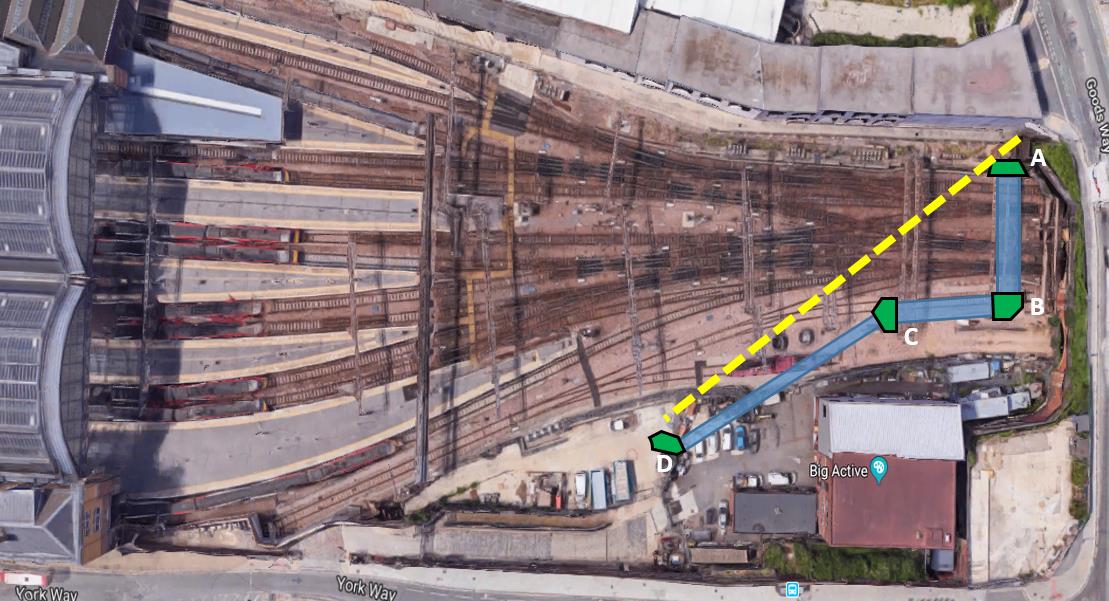

In all, four chambers, 22m of double bore culvert, 50m of single bore culvert adjacent to track and 25m of double bore culvert directly under the track was required for this scheme.

Close collaboration with Morgan Sindall and Network Rail was an essential part of the success of this challenging and complex project.

2020

Year

£3,500,000

Overall Value

MORGAN SINDALL / NETWORK RAIL

Client

Tony Goble

Contact

The Challenge

We proposed a solution that would flume the existing brick egg sewer in two locations and would ensure protection of the sewer and allow over pumping in order to install the final section during a blockade. Spoor-Tech have undertaken a large and varied portfolio of similar solutions and we were confident that all stakeholders would see this solution as lowering the risk to the sewer and the operational railway.

The segmental steel flumes were installed within the sewer in small sections, once in place the chambers A and D were excavated around the flumes and the new chambers constructed with no impact on the flow of the sewer. The flumes were left in place for the duration of the off-line works and removed during the blockade to bring the new culverts on-line and allow the demolition of the now redundant brick sewer.

Off-Line Works

All chambers could be constructed adjacent to the operational railway, as well as a single bore culvert section and a twin bore section. This would leave a last section of culvert that could only be completed in a blockade, with the track removed.

The design was progressed to allow chambers to be constructed and the culverts installed between and backfilled as the works progressed to allow access to site for a number of other projects within the larger scheme.

Chamber A presented a challenge due to the discovery of buried structures, and had to be dug completely by hand in sections in order to protect the adjacent railway and major development alongside the chamber.

Christmas Blockade

Christmas 2020 brought a number of challenges, which meant that the last chamber was completed just two days before the blockade and was essential to the project completion.

With London in the midst of a pandemic and under severe restrictions the works were planned to proceed. All materials were delivered to site to enable the works, including culvert sections, aggregates and concrete required for a 9 day blockade, the logistics and planning was a major challenge under the circumstances.

In order to co-ordinate the larger works we programmed the works to allow 4 days to remove two sets of track, install culverts and backfill the area before laying new track. The second phase could only progress once the new track was in place and 4 days was programmed for phase 2 and repeating the process for the second half of the works.

Click Here for a year long time-lapse of the project.